Casting Services

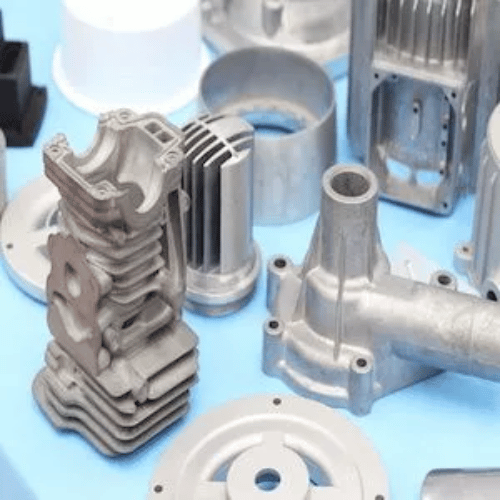

Frigate offers a comprehensive suite of B2B casting services, providing high-quality, near-net-shape components for your demanding projects. Our technical expertise ensures optimal part performance and cost-effective production.

What We Do

Our Casting Offerings

Partner with Frigate Engineering and unlock new technical expertise for your B2B manufacturing projects.

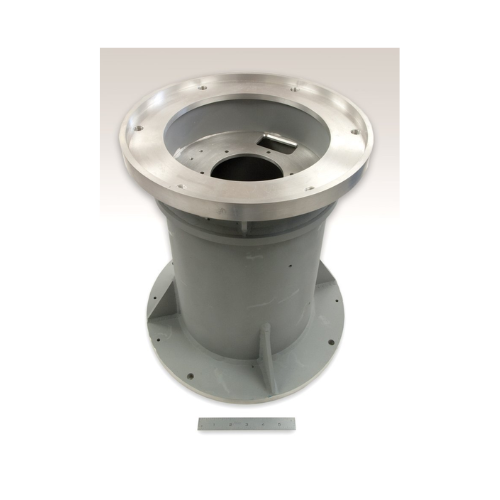

Hot Chamber Casting

Ideal for large quantities of complex, thin-walled parts with excellent dimensional accuracy and repeatability. Due to the limitations of the hot chamber design, it is primarily used for low-melting-point alloys like aluminum, magnesium, and zinc. Automated ladling systems and robust process controls ensure consistent quality and minimal operator intervention. Short solidification times in the heated die enable fast production cycles, maximizing output.

Cold Chamber Casting

Cold chamber design allows for wider material selection, including higher melting point alloys like brass and steel. It also accommodates the casting of larger and thicker-walled components compared to HPDC. Manual pouring and higher set-up times require careful planning and skilled operators. Metal is injected under high pressure, minimizing turbulence and promoting better directional solidification for superior mechanical properties.

Aluminum Casting

Aluminum offers an excellent balance of strength, weight, and corrosion resistance, making it a popular choice for various applications. Aluminum’s favorable solidification characteristics allow for intricate shapes and good surface finishes, which are achievable through various casting methods. Aluminum’s versatility allows casting through HPDC, CCDC, sand casting, and investment casting, depending on complexity and production volume needs.

Zinc Casting

Zinc offers a cost-competitive option for applications requiring good dimensional accuracy, corrosion resistance, and a pleasing aesthetic finish. Zinc’s low melting point translates to lower energy consumption during casting and faster cycle times. Zinc castings possess lower mechanical strength compared to other metals. Applications are often limited to decorative or non-load-bearing parts. Zinc’s properties make it well-suited for high-volume production using the HPDC method.

Investment Casting

The lost wax process allows for intricate geometries, tight tolerances, and excellent surface finishes, which are ideal for complex, high-precision components. Due to the non-reusable mold design, investment casting accommodates a broader range of materials, including ferrous and non-ferrous alloys. The intricate mold-making process and relatively low production volume make investment casting more expensive compared to other methods.

Sand Casting

Sand casting is a highly versatile process suitable for various casting sizes, complexities, and materials. Due to its relatively simple mold-making process, sand casting offers a cost-effective solution for prototypes or small-batch production runs. Sand casting can accommodate a vast array of materials, including ferrous and non-ferrous alloys. Compared to other methods, sand casting generally has lower dimensional accuracy, requiring potential post-processing for precise fits.

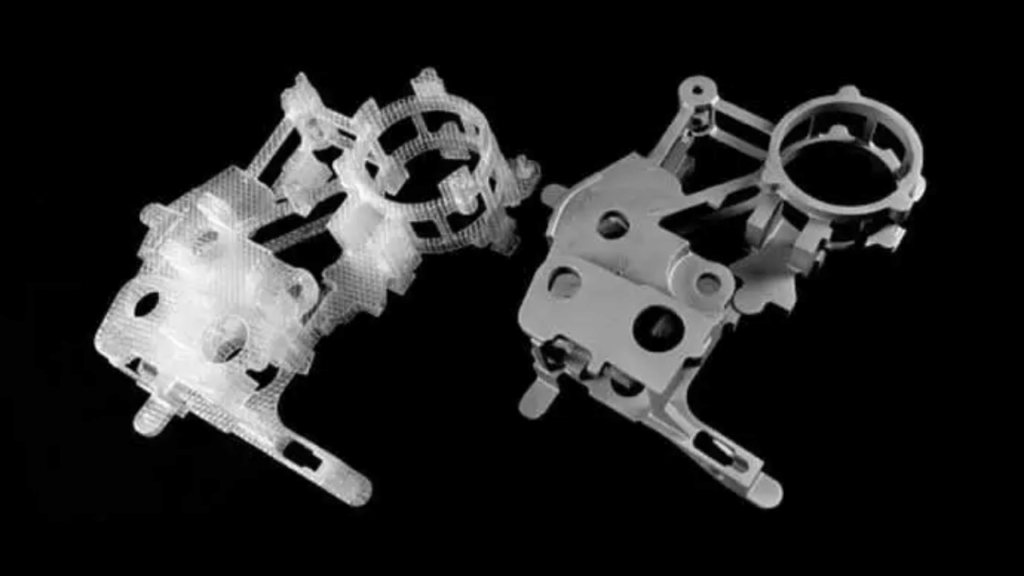

Rapid Prototype Casting

Rapid prototyping casting techniques (e.g., 3D printing casting patterns) enable fast creation of functional prototypes for design verification and testing. Material selection for rapid prototype casting may be limited compared to traditional methods. Rapid prototype casting can be a valuable tool in the early stages of product development before transitioning to high-volume production methods. It identifies potential design issues early and facilitates design optimization before full-scale production.

Get Your Quote Now

- Instant Quotation

- On-Time Delivery

- Affordable Cost

Multi-Disciplinary Casting Expertise

Precision Engineered for Performance

We leverage a deep understanding of material properties, solidification mechanics, and mold design principles to optimize casting processes for your specific requirements.

Advanced Simulation & Modeling plays a crucial role in our casting solutions. We simulate casting processes to predict potential solidification defects and optimize gating systems for exceptional directional solidification and microstructure control.

Our Business Verticals

Automotive

Aerospace

Marine

Railway

Construction and Infrastructure

Energy and Power Generation

Industrial Machinery

Defense and Military Equipment

Technical Advantages of Frigate

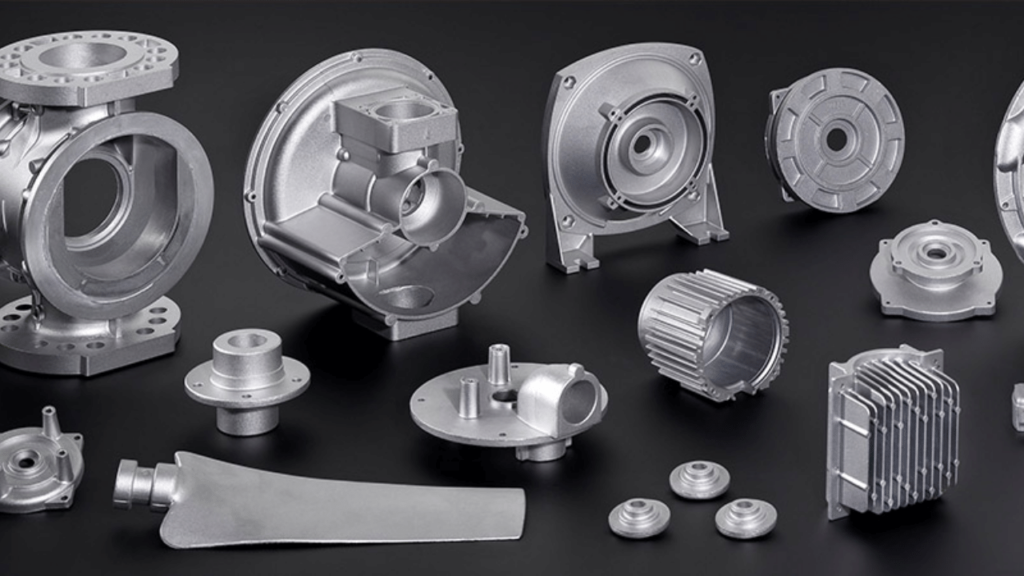

Diverse Casting Processes

We offer a wide range of casting techniques to suit your specific project requirements. These include sand casting, investment casting, die casting, and lost-foam casting, each with its own advantages for part complexity, dimensional accuracy, and material suitability.

Our team of experts will guide you in selecting the most appropriate process for your application.

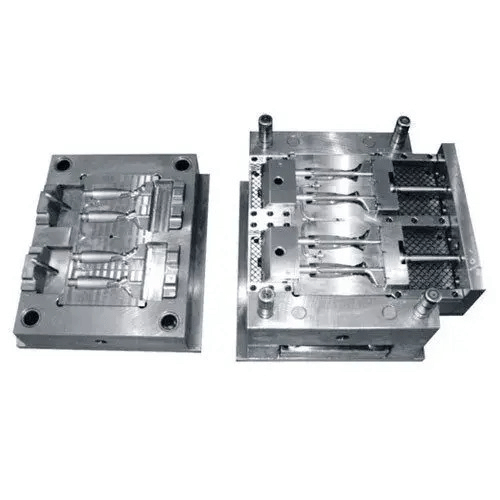

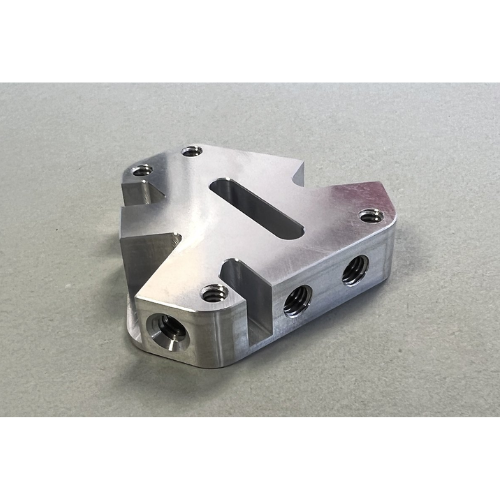

Advanced Molding Techniques

We utilize state-of-the-art molding technologies, including 3D printing for mold creation, to ensure exceptional dimensional accuracy and repeatability in your castings.

Certified Material Expertise

Our team possesses in-depth knowledge of various casting materials, including ferrous and non-ferrous alloys. We can recommend the optimal material based on your project’s specific strength, weight, corrosion resistance, and other performance requirements.

Advanced Finishes for Premium Performance

When you require high-performance or distinctive aesthetics, Frigate delivers with our advanced finishes,

Anodizing (Aluminum)

It provides corrosion resistance with optional wear resistance for demanding applications.

Wet Painting

Unlimited color choices for complete customization.

Plating

Enhance performance with nickel, chrome, and other options.

Chemical Film (Aluminum)

Improves paint adhesion and guards against corrosion, all while maintaining conductivity.

Media Tumbling

Smooth surfaces and eliminate sharp edges for a polished finish.

Why Choose Frigate for Custom Casting?

Rigorous Quality Control

Frigate Engineering adheres to strict quality control procedures throughout the casting process. We employ advanced inspection techniques such as X-ray, ultrasonic testing, and dimensional analysis to ensure castings meet your specifications and industry standards.

Finite Element Analysis (FEA) Integration

Our in-house FEA capabilities allow us to analyze casting designs for potential stress points and optimize them for strength and performance. This minimizes the risk of casting defects and ensures parts can withstand intended loads and operating conditions.

Advanced Inspection Techniques

We utilize CMMs, ultrasonic testing, and other non-destructive testing (NDT) methods to verify dimensional accuracy, material properties, and weld integrity. This guarantees parts meet your exact specifications and comply with industry standards.

Casting Materials

Our casting services offer a fusion of precision and creativity, molding metals into bespoke designs with finesse. Whether it’s iron’s resilience or bronze’s fluidity, we bring your visions to life with expert craftsmanship.

Cast Metal Materials

Aluminum Casting

Aluminum alloys are the most widely used for cast parts. Aluminum casting suppliers benefit from the total recyclability of the material and its ease of use. Due to the comparatively higher melting point, aluminum casting may require a cold chamber casting process. Engineers use cast aluminum parts primarily for their great strength-to-weight ratios, dimensional stability, and diverse finishing options. Some of the other common characteristics of cast aluminum alloys are:

- Withstand high operating temperatures

- Corrosion Resistance

- Good stiffness

- High thermal and electrical conductivity

Engineers and designers can choose from various alloys for their aluminum casting parts. Frigate offers the most popular aluminum casting alloys, including:

- A360.0

- A380.0

- A383.0 (ADC12)

- A413.0

Zinc Casting

Zinc is the easiest to cast material among the casting metals and is typically used in hot chamber processes. Molten zinc has exceptional casting fluidity and a lower melting point. Its strength and stiffness allow it to produce parts with thinner walls and highly detailed features and maintain tight tolerances. The low melting point of casting zinc alloys means the casted parts cool off and solidify more quickly, which results in the fastest production rates of the casting materials. Zinc is an all-around well-performing material due to its balance of mechanical and physical characteristics, which include,

- Impact strength

- High hardness

- Great stability

- High-quality surface finish and easily plated

- Low melting point

Frigate offers the most popular types of Zamak and ZA casting zinc alloys. More specifically, those alloys include,

- Zamak 2 (ZA-2)

- Zamak 3 (ZA-3)

Casting Finishes

Standard (As-Cast)

Zinc and aluminum zinc parts can be left as-cast and retain reasonable corrosion resistance. Aluminum parts must be coated to achieve corrosion resistance. Cast parts are typically broken away from the casting sprue, leaving rough marks at the gate locations. Most castings will also have visible marks left by the ejector pins. The surface finish for as-cast zinc alloys is commonly 16-64 microinch Ra.

Bead Blasted

The part surface is left with a smooth, matte appearance.

Anodized (Type II Or Type III)

Aluminum is typically anodized. Type II anodizing creates a corrosion-resistant oxide finish. Although suppliers can anodize parts in different colors, the surface of a cast part does not facilitate a cosmetic finish with anodizing. Type III is a thicker finish and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II. Anodized coatings are not electrically conductive.

Powder Coating

All cast parts can be powder coated. This is a process where powdered paint is electrostatically sprayed onto a part, then baked in an oven. Powder coating creates a strong, wear- and corrosion-resistant layer that is more durable than standard wet painting methods. A wide variety of colors are available to create the desired aesthetic.

Wet Painting

All cast parts can be wet painted in a wide variety of paint formulations and colors.

Plating

Cast parts can be plated with electroless nickel, nickel, brass, tin, chrome, chromate, Teflon, silver and gold.

Chemical Film

Suppliers can apply a chromate conversion coat to protect aluminum from corrosion and improve the adhesion of paints and primers. Chemical film conversion coatings are electrically conductive.

Media Tumbled

Cast materials are subjected to vibratory media tumbling to remove sharp edged and smooth surfaces.

Frigate Approach

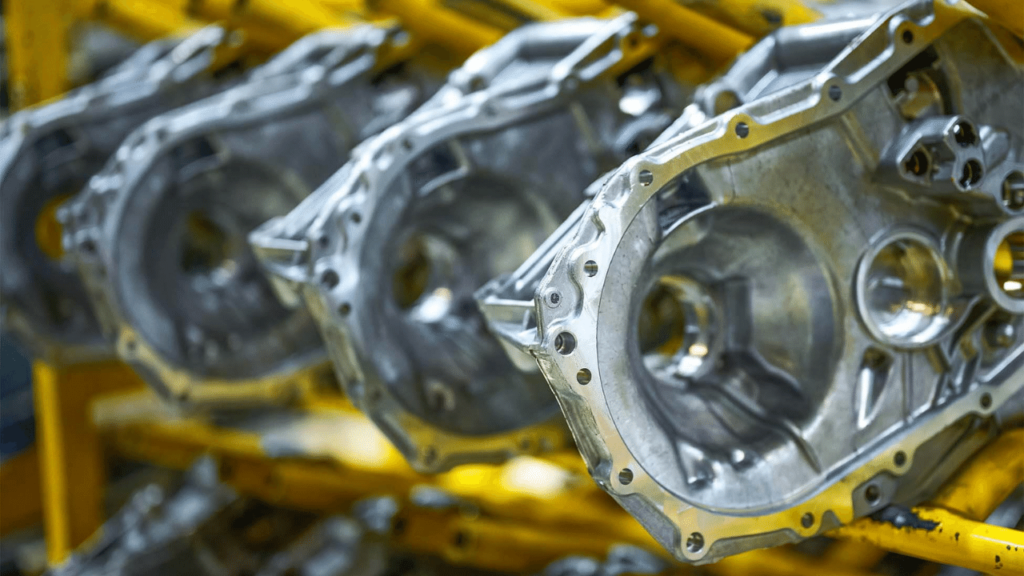

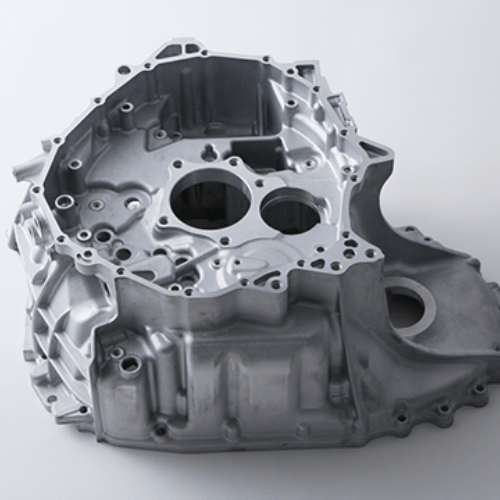

Frigate's Pressure & Gravity Casting Solutions

Frigate delivers unparalleled expertise across both Pressure and Gravity Casting processes. We excel in producing complex, high-quality parts for the automotive and transportation industries.

Our Pressure Casting capabilities encompass intricate components like two-wheeler crankcases, Vehicle Clutch Housings, and Vehicle Gear Box Housings.

Furthermore, our Gravity Casting mastery extends to crafting visually striking and functional parts such as Two Wheeler Alloy Wheels, Disc + ABS Brakes, and Two Wheeler Swing Arms. Frigate is your one-stop shop for exceptional casting solutions.

What Our Customers Say about Frigate

21%

Faster Manufacturing

Having Doubts? Our FAQ

Check all our Frequently Asked Question

What is casting?

Casting is a manufacturing process that involves pouring molten metal into a mold cavity and allowing it to solidify. Once cooled, the solidified metal takes the shape of the mold cavity, creating a cast part.

What are the benefits of casting?

Casting offers several benefits, including:

- Ability to produce complex shapes and sizes.

- Cost-effectiveness for high-volume production.

- Material flexibility with various metals, plastics, and ceramics.

- Design freedom for intricate details.

- Strength and durability of cast components.

What materials do you offer for casting?

We offer a wide range of casting materials, including aluminum, zinc, and various alloys. Our team can help you choose the right material for your specific application.

What is the difference between standard and custom die casting?

Standard casting uses pre-existing molds to mass-produce identical parts. Custom casting involves designing and creating a unique mold to produce parts according to your requirements.

What are the benefits of custom casting?

Custom casting offers several advantages, including:

- Production of parts with unique shapes and features.

- Optimization for better performance and efficiency.

- Reduced costs through design optimization.

How can I get a quote for a casting project?

Contact Frigate Manufacturing today! We’ll talk about your project requirements and give you a competitive quote.

Manufacturing Capacity

Ferrous casting

Mold size(max): 1m X 1m

Weight Range: 1 KG ~ 30 KGS

Mold size(max): 1.5m X 1.5m

Weight Range: 30 KG ~ 150 KGS

Mold size(max): 3m X 3m

Weight Range: 100 KG ~ 1000 KGS

Mold size(max): 500 MM X 500 MM

Weight Range: 0.250 KG ~ 20 KGS

Mold size(max): 500 MM X 500 MM

Weight Range: 0.100 KG X 20 KGS

Non-ferrous casting

Capacity: 5000 MT/a

Range of weight: 100 gm to 20 KGS

Mold size(max): 1 M X 1 M

Weight Range: 0.5 KG X 50 KGS

Forging

Capacity: 20,000 Tons per Annum

Range of weight: 300 KG to 1 Ton

Hammering: 5 Ton

Range of weight: 0.2 KG to 200 KGS

Hammering: 1600 Ton Hydraulic press

Ring size: 350 MM OD to 3000 MM OD

Range of weight: 15 KGS to 3200 KGS

Materials

Carbon Steel, Stainless Steel (AUSTENITE), Alloy Steel, Stainless Steel (MARTENSITE), etc.

Machining

Materials

Steel, Aluminum, Brass, Copper, Titanium, Nickel Alloys, Tungsten Carbide, etc.

Plastics

1250 X 1250 MM

Within 10 microns

Materials

Engineering Plastics, Polyethylene, Polypropylene, Polyvinyl chloride, Polyethylene terephthalate, Bioplastics, etc.

Rubber

Materials

Natural rubber, Styrene-Butadiene Rubber, Nitrile Butadiene Rubber, Silicone Rubber, Fluorocarbon Rubber, Recycled Rubber, etc.

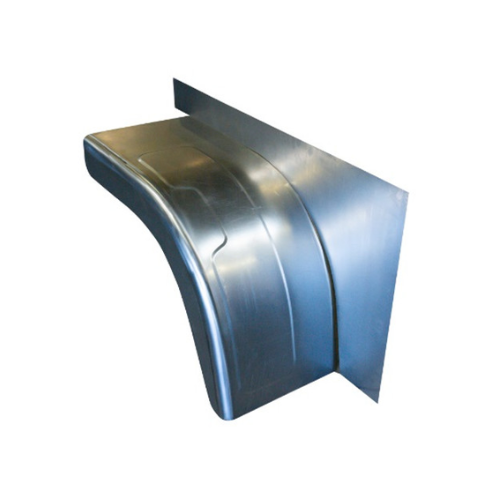

Sheet Metal Fabrication

Sheet Thickness

Materials

Mild Steel, Stainless Steel, Aluminum, Brass, Copper, etc.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Global Sales Office

818, Preakness lane, Coppell, Texas, USA – 75019

Registered Office

23, 6th West Street, Balaji Nagar, Kattur, Pappakuruchi, Tiruchirappalli-620019, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ